Thread Starter

#21

- Messages

- 46

- Likes

- 8

- City

- LOUISVILLE

- State

- KY

- Country

- United States

- What I Drive

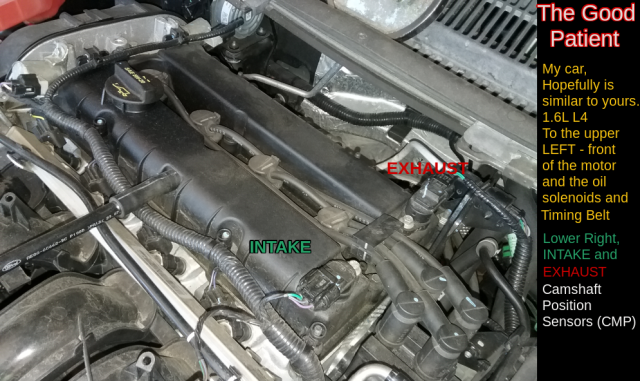

- 2016 Fiesta Titanium Hatchback

Thread Starter

#21

The damage I see of your incident tells me the A/C - ABS braking system or the passenger side (internal fuse and relay box and even the BCM) can be affected by this.

You may not have issues with the PCM, but with the flex/bending of the passenger side and how it can affect the Body control Module - the inside fuse box (behind the Glove box) may hold clues on this.

You may not have issues with the PCM, but with the flex/bending of the passenger side and how it can affect the Body control Module - the inside fuse box (behind the Glove box) may hold clues on this.

Andy,

Thanks for the reply. I'm not sure but perhaps you missed it or I may not have told you, the accident that the happened was over a year ago. 3/29/23. Keep in mind when I received the payout on that it allowed me to do a complete tune up.

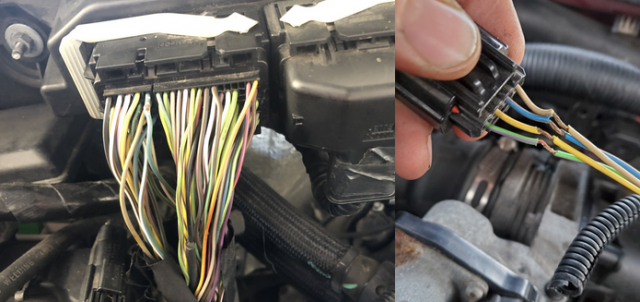

Starting with wiring that led light to the same fuse that supplies the components that are throwing all the codes, and this particular problem started in April 2024.

Now in April a month after the led wiring my daughter tore off the passenger side mirror. Totally unrelated to the 2023 accident.

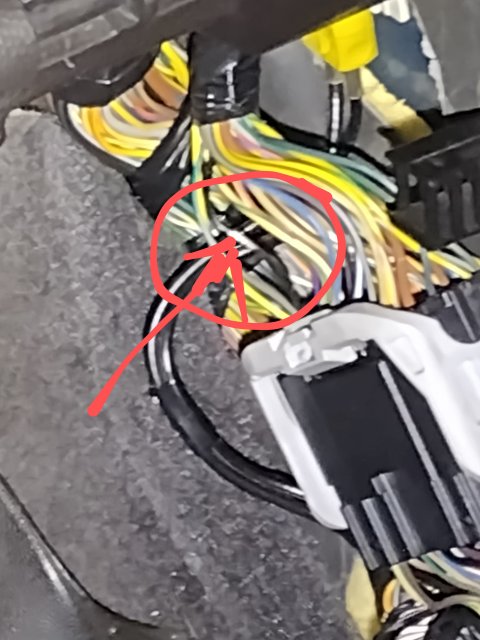

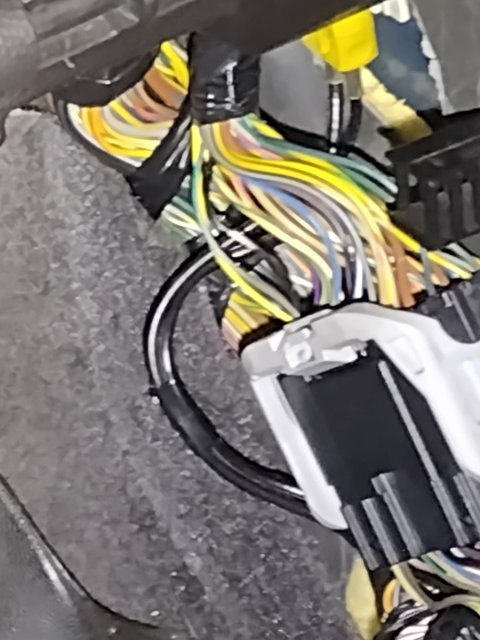

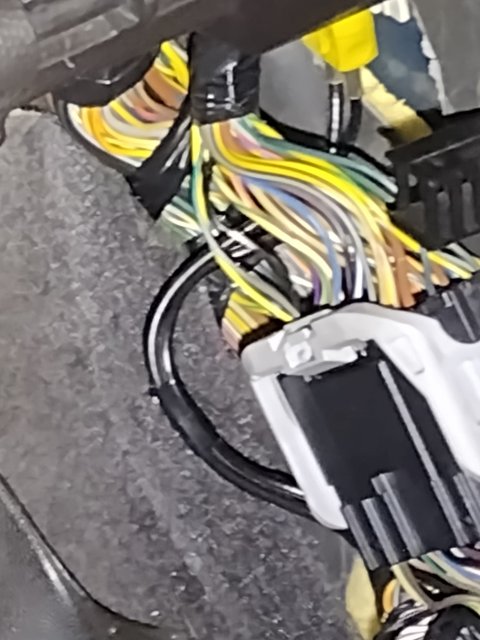

It was the 2024 incident, the mirror, where the very next day I had to jump start the car. After that all this cascading of codes started. I already checked every fuse in every box on the car. Surprisingly that box behind the glove box was the hardest to test. The way it sits was nearly impossible to get comfortable testing each fuse. Maybe I should check again but for the record it was tested once.

I hope it's just me but I'm feeling like your just as frustrated trying to help as I am trying to diagnose.

Please don't give up yet.

I haven't.

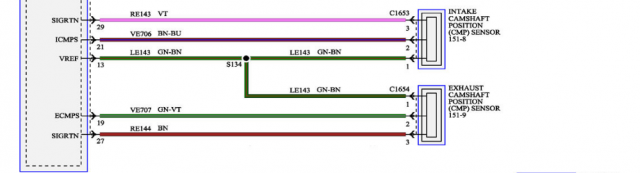

Alldata has given me a bunch of information and step by step troubleshooting guides. (If yes go to xx if no go to xx type of troubleshooting)

It's going to take some time to do all this as a lot of it is pin-out troubleshooting. Remember I said electrical is not my strong suit.

With that said can you give me any advice on how to do all this testing without accidentally blowing the PCM?

Do I disconnect the PCM to check the pins forward and back checking for shorts or broken wires?

I also do not know why the PCM and other control modules will not reset after a week long disconnect of the battery? I feel like if I could start with a clean slate these issues may solve themselves.

I learned that even in a crank no start the PCM will still throw codes. Like the new P06B8 and P0882 codes.

I have accepted the fact that due to my lack of experience with new vehicles this is going to be a very long process.

Please, I do not care how long of an answer you give I will read the entire post.

Can you give me your best advice for carrying out this kind of diagnostic troubleshooting?

Thanks.