So, first off let's learn or relearn the facts about winter tires.

How do winter tires work?

Here are a few pictures to illustrate the mechanics involved in winter traction.

If you look closely at a road surface you can tell that it is really not that smooth as represented by the model in this picture:

With the high grip rubber compound used in your summer performance tires the contact area conforms to the irregular surface of the road:

That amount of contact can generate a tremendous amount of traction in the summer time but what if the road in snow covered?

That brings us to the question, what makes a tire a good winter tire? The answer is a three part puzzle and without all three parts traction will be compromised.

Let's look at the first part of the puzzle; tread design.

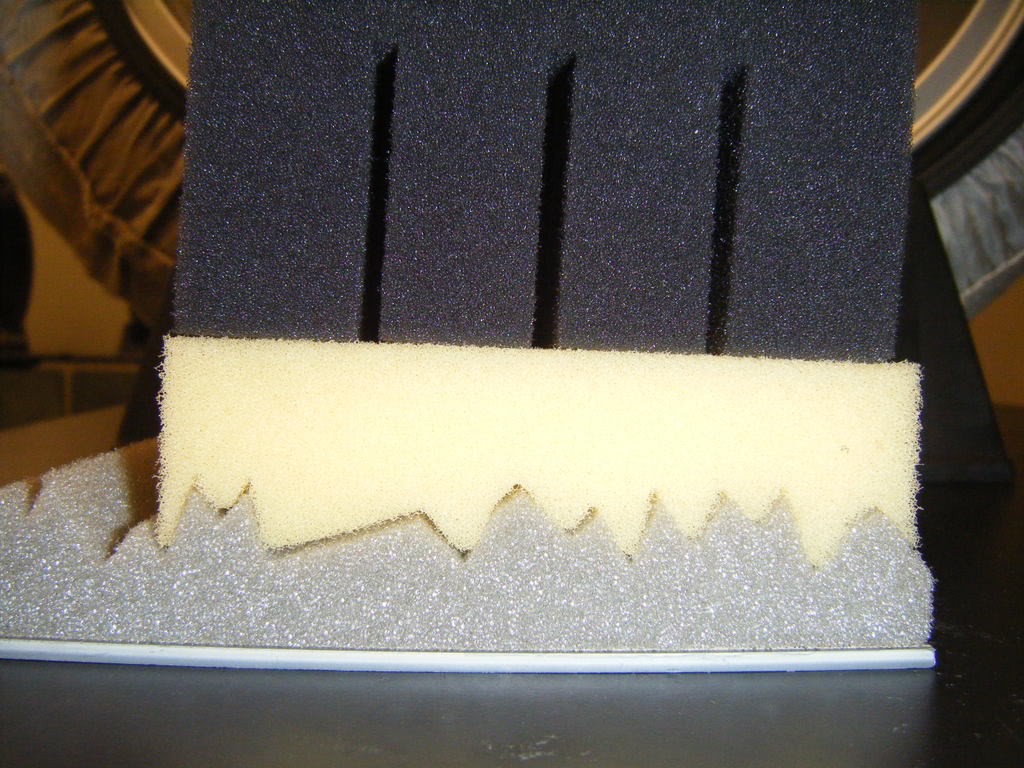

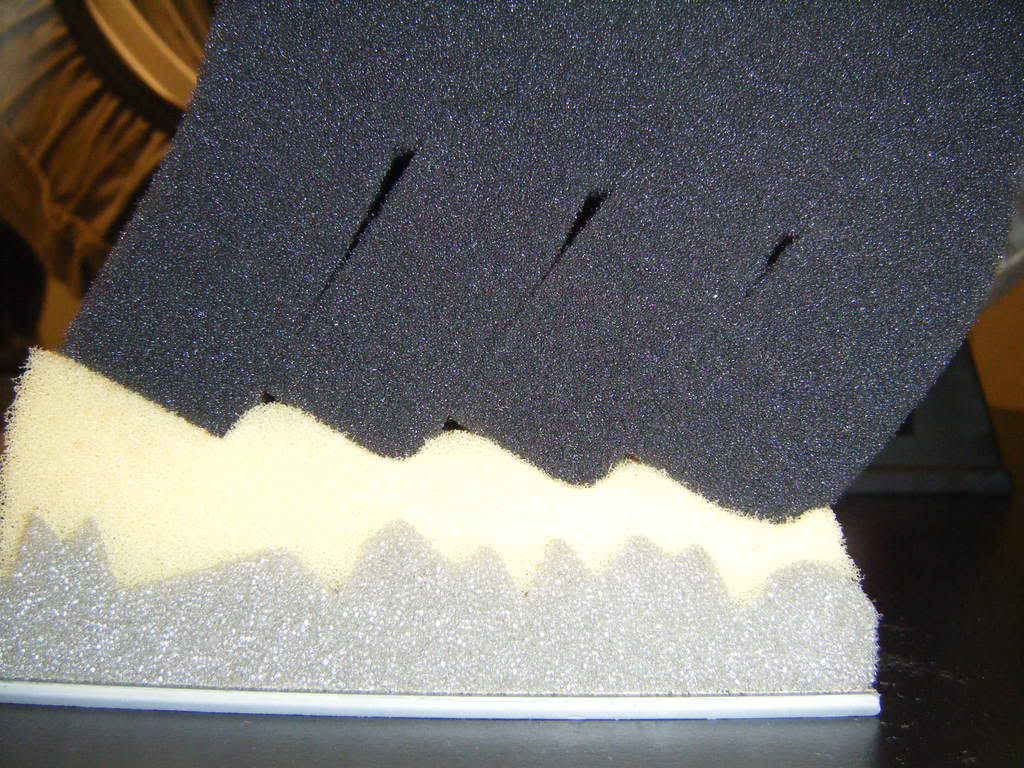

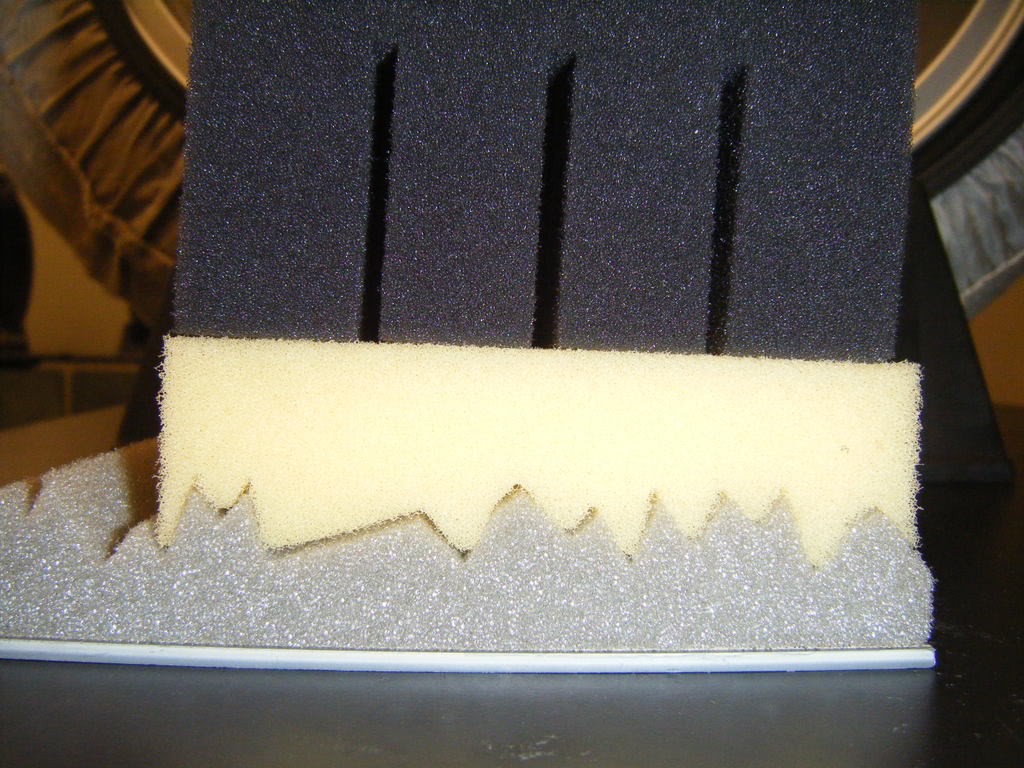

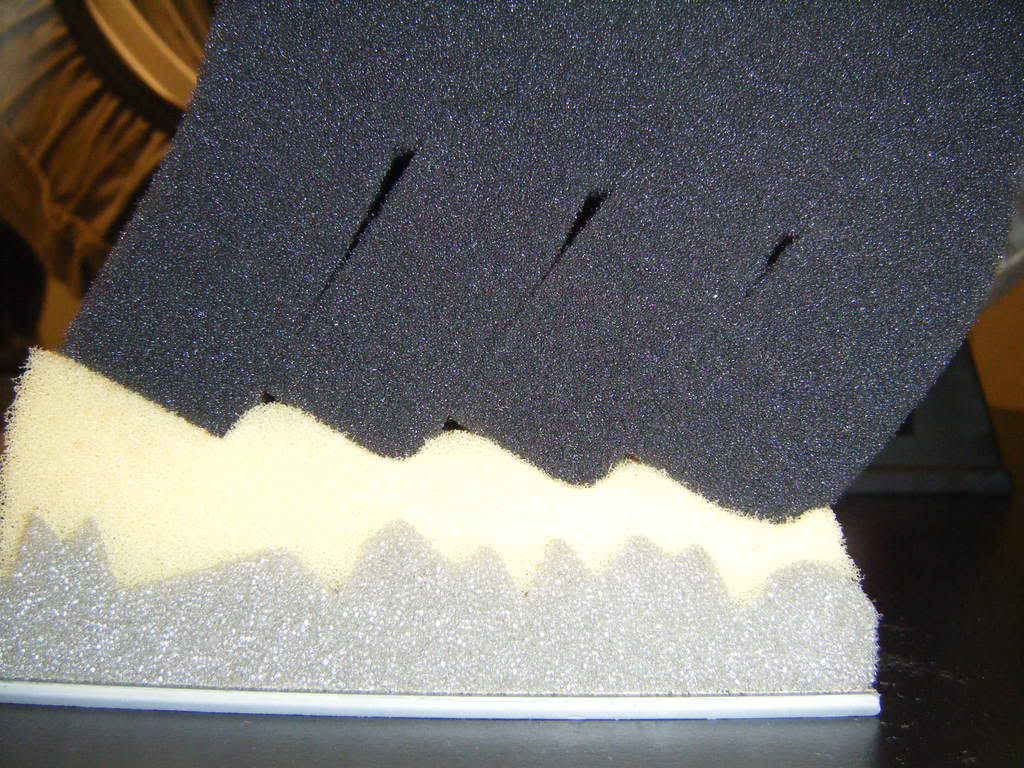

This picture shows a winter tire tread design which, as you can clearly see, utilizes a large number of sipes:

When the road gets snow covered the tire is no longer able to conform to the surface.

The siping allows the tread elements to flex under stress create aggressive "biting edges" when braking, cornering or accelerating.

Part two of our three piece traction puzzle is tread depth.

While deep snow and ice-covered roads are two of the most challenging conditions North American drivers will face, tire developments during the last decade have noticeably advanced wintertime mobility. The technological revolution of dedicated winter tires for drivers in the snowbelt, and the continuing evolution of all-season tires for drivers living on its periphery characteristically offer more grip in snow and on ice than ever before.

However the basics of delivering traction and handling in snow and on ice remain unchanged. Tires must combine three fundamental features to deliver good wintertime performance, including an appropriate tread design, pliable tread compound and sufficient tread depth. If any one of these fundamental features is absent then the other two, regardless of their ability, cannot deliver the desired results. Since engineers can develop cutting-edge tread designs and chemists can develop advanced rubber compounds, it is often the remaining tread depth that is the variable in determining wintertime performance.

In most parts of the world, tires are considered to be legally worn out when they reach "2/32" (approximately 1.6mm) of remaining tread depth. U.S. law requires tires to have easy-to-see Tread Wear Indicator bars running from one side of their tread design to the other when the tire's tread has worn down to the minimum legal limit of 2/32 inch.

However in spite of the legal minimums, it's recommended that drivers expecting to experience wet conditions consider replacing their tires when they reach 4/32" of remaining tread depth. Tire Rack tests have shown how shallow treads reduce wet braking traction and increase stopping distances.

We also recommends that drivers expecting to encounter snow-covered roads consider replacing their tires when they reach approximately 6/32" of remaining tread depth to maintain good mobility. Tires need more tread depth in wintry conditions to compress snow in their grooves and release it as they roll. If there isn't sufficient tread depth, the "bites" of snow that can be processed on each tire revolution will be reduced to "nibbles," and the vehicle's traction and mobility in snow will be reduced.

The third and final part of the puzzle is the rubber compound used. Rubber compounds vary widely from manufacturer to manufacturer but, the task is the same so, you will see similarities between the products. They all typically use compounds which utilize materials designed to remain flexible at cold temps in addition to traction enhancements from silica and other materials which add more bite on ice.

--------------------------------------------------------------

Now, for the next step ... types of winter tires

There are basically three different types of winter tires

#1.) Performance Winter

You want enhanced dry road handling from your winter tires and are willing to trade some snow and ice traction to get it.

Meeting severe snow service requirements and branded with the "Snowflake-on-the-Mountain" symbol, these are higher speed rated tires that are designed to suit winter driving on European highways. They are available in many of the low profile sizes used as Original Equipment on sporty imported and domestic cars. Due to their unique designs these tires must be installed in sets of four.

#2.) Studless Ice and Snow

You want to maximize snow and ice traction from your winter tires without the inconvenience of using winter tire studs.

Meeting severe snow service requirements and branded with the "Snowflake-on-the-Mountain" symbol, these tires feature the latest in tread compound technology to provide winter traction without the inconvenience of tire studs. They trade a little handling for excellent ice and snow traction. Due to their unique tread compounds these tires must be installed in sets of four.

#3.) Studdable Winter

You want the traditional security of studded winter tires for enhanced traction on ice.

Meeting severe snow service requirements and branded with the "Snowflake-on-the-Mountain" symbol, these tires feature traditional snow tire tread compounds and studdable tread designs for good snow and ice traction. Due to their unique designs these tires must be used in sets of four. Use of studded tires is often prohibited or restricted. Check with local authorities to confirm legality. Keep in mind that these can be used without studs if desired.

But Do I Really Need Winter Tires?

The primary concern that our customers express is that they don't want to get "stuck" in the snow (or in the ditch) during the winter.

While in cities like Atlantic City, Memphis and Seattle located at the edge of the snow belt, relatively new All-Season tires will probably work just fine. But the odds change as you move further into the snow belt or the All-Season tires have a few years of wear on them. And who wants to gamble...especially when their collision deductible and future insurance premiums are on the table.

We all know that tires are a compromise. One tire can't be the fastest on the track, most controllable in the snow, and longest wearing. The Ultra High Performance tire that grips the track with tread temperatures of 200? is incompetent as its tread compound becomes like "hard plastic" at below 32?. Today's 80,000-mile tires require tread designs and compounds that maximize long, even wear... not winter traction. And while many of today's all-season tires (Original Equipment, touring and performance) address some of these issues, they still emphasize longer wear, a quieter ride or greater performance...not winter traction.

Only winter tires are designed to excel in the colder temperatures, slush, snow and ice that many parts of the country experience for three or more months a year.

It's also important to note that the recent advancements in electronic driver aids, such as ABS and traction control don't provide more traction. They only help prevent drivers from over braking or overpowering the available traction of their tires. The only thing the driver can do to increase traction...to actually get more grip and control... is install better tires.

Special thanks to Tire Rack for the information.

How do winter tires work?

Here are a few pictures to illustrate the mechanics involved in winter traction.

If you look closely at a road surface you can tell that it is really not that smooth as represented by the model in this picture:

With the high grip rubber compound used in your summer performance tires the contact area conforms to the irregular surface of the road:

That amount of contact can generate a tremendous amount of traction in the summer time but what if the road in snow covered?

That brings us to the question, what makes a tire a good winter tire? The answer is a three part puzzle and without all three parts traction will be compromised.

Let's look at the first part of the puzzle; tread design.

This picture shows a winter tire tread design which, as you can clearly see, utilizes a large number of sipes:

When the road gets snow covered the tire is no longer able to conform to the surface.

The siping allows the tread elements to flex under stress create aggressive "biting edges" when braking, cornering or accelerating.

Part two of our three piece traction puzzle is tread depth.

While deep snow and ice-covered roads are two of the most challenging conditions North American drivers will face, tire developments during the last decade have noticeably advanced wintertime mobility. The technological revolution of dedicated winter tires for drivers in the snowbelt, and the continuing evolution of all-season tires for drivers living on its periphery characteristically offer more grip in snow and on ice than ever before.

However the basics of delivering traction and handling in snow and on ice remain unchanged. Tires must combine three fundamental features to deliver good wintertime performance, including an appropriate tread design, pliable tread compound and sufficient tread depth. If any one of these fundamental features is absent then the other two, regardless of their ability, cannot deliver the desired results. Since engineers can develop cutting-edge tread designs and chemists can develop advanced rubber compounds, it is often the remaining tread depth that is the variable in determining wintertime performance.

In most parts of the world, tires are considered to be legally worn out when they reach "2/32" (approximately 1.6mm) of remaining tread depth. U.S. law requires tires to have easy-to-see Tread Wear Indicator bars running from one side of their tread design to the other when the tire's tread has worn down to the minimum legal limit of 2/32 inch.

However in spite of the legal minimums, it's recommended that drivers expecting to experience wet conditions consider replacing their tires when they reach 4/32" of remaining tread depth. Tire Rack tests have shown how shallow treads reduce wet braking traction and increase stopping distances.

We also recommends that drivers expecting to encounter snow-covered roads consider replacing their tires when they reach approximately 6/32" of remaining tread depth to maintain good mobility. Tires need more tread depth in wintry conditions to compress snow in their grooves and release it as they roll. If there isn't sufficient tread depth, the "bites" of snow that can be processed on each tire revolution will be reduced to "nibbles," and the vehicle's traction and mobility in snow will be reduced.

The third and final part of the puzzle is the rubber compound used. Rubber compounds vary widely from manufacturer to manufacturer but, the task is the same so, you will see similarities between the products. They all typically use compounds which utilize materials designed to remain flexible at cold temps in addition to traction enhancements from silica and other materials which add more bite on ice.

--------------------------------------------------------------

Now, for the next step ... types of winter tires

There are basically three different types of winter tires

#1.) Performance Winter

You want enhanced dry road handling from your winter tires and are willing to trade some snow and ice traction to get it.

Meeting severe snow service requirements and branded with the "Snowflake-on-the-Mountain" symbol, these are higher speed rated tires that are designed to suit winter driving on European highways. They are available in many of the low profile sizes used as Original Equipment on sporty imported and domestic cars. Due to their unique designs these tires must be installed in sets of four.

#2.) Studless Ice and Snow

You want to maximize snow and ice traction from your winter tires without the inconvenience of using winter tire studs.

Meeting severe snow service requirements and branded with the "Snowflake-on-the-Mountain" symbol, these tires feature the latest in tread compound technology to provide winter traction without the inconvenience of tire studs. They trade a little handling for excellent ice and snow traction. Due to their unique tread compounds these tires must be installed in sets of four.

#3.) Studdable Winter

You want the traditional security of studded winter tires for enhanced traction on ice.

Meeting severe snow service requirements and branded with the "Snowflake-on-the-Mountain" symbol, these tires feature traditional snow tire tread compounds and studdable tread designs for good snow and ice traction. Due to their unique designs these tires must be used in sets of four. Use of studded tires is often prohibited or restricted. Check with local authorities to confirm legality. Keep in mind that these can be used without studs if desired.

But Do I Really Need Winter Tires?

The primary concern that our customers express is that they don't want to get "stuck" in the snow (or in the ditch) during the winter.

While in cities like Atlantic City, Memphis and Seattle located at the edge of the snow belt, relatively new All-Season tires will probably work just fine. But the odds change as you move further into the snow belt or the All-Season tires have a few years of wear on them. And who wants to gamble...especially when their collision deductible and future insurance premiums are on the table.

We all know that tires are a compromise. One tire can't be the fastest on the track, most controllable in the snow, and longest wearing. The Ultra High Performance tire that grips the track with tread temperatures of 200? is incompetent as its tread compound becomes like "hard plastic" at below 32?. Today's 80,000-mile tires require tread designs and compounds that maximize long, even wear... not winter traction. And while many of today's all-season tires (Original Equipment, touring and performance) address some of these issues, they still emphasize longer wear, a quieter ride or greater performance...not winter traction.

Only winter tires are designed to excel in the colder temperatures, slush, snow and ice that many parts of the country experience for three or more months a year.

It's also important to note that the recent advancements in electronic driver aids, such as ABS and traction control don't provide more traction. They only help prevent drivers from over braking or overpowering the available traction of their tires. The only thing the driver can do to increase traction...to actually get more grip and control... is install better tires.

Special thanks to Tire Rack for the information.