Hmmm. If you have problems with that actuator - if you have the original - then the arms and the throw have to the same (that push rod) you should have no change in size of anything.

So when I disconnect the battery and restart the car I’m selecting the floor vents even without the air distribution lever arm attached?

Yes, I meant you see operation and feel air - if using the floor vent when all the system is running - does it only push air to the floor vents - not leaking out considerably thru others?

What I'm trying to diagnose here, is if the Actuators built in sensors - are working and communicating correctly or is the drums actual position off to actuators thinking - as if; EATC tells the actuator to move here, but the Drum stops moving and hits it's limit stop (not limit switch) and the actuator keeps pushing until it breaks.

Turn off the whole system - does any erroneous noises like clack clack or strong thunks or any binding noises heard?

Operate the controls and Watch the Actuator too - it may move more than it should - so that may indicate one; the actuator range is not correct - two; the EATC is looking for a value that actuator can't attain so it fails by breaking the arm - or three; hopefully a simpler one, the Drum is out of alignment to the actuator turn - so the drum just needs to have itself re-centered to the actuator gear

Then when it does the self-test - that point seems to be where most of these errors by my references and experiences with both theirs and my system - the arm snaps when the binding occurs - but it makes a considerable groaning noise and even makes a section of the air vent either lower or center console move then SNAP - you can even see it "bounce" - you may even see dust lift out of the vent when the break occurs.

There are several approaches but one main one is it's relearn process - for that should happen by itself when you reconnect the battery and let it operate thru the settings you select.

That's why I mentioned the effort, for if you had it apart and just wanted to find floor - pull the battery - reconnect; then you simply connected the unmounted actuator to the connector.

Leave it unmounted and just watch it's operation by seeing how that (actuators) cog turns - the actuator that controlled the drum, (for example) turn on the regular heat setting and watch it turn;

Try to watch for;

- the direction it rotates and count the turns

- - because you'll have to then rotate the drums' gear in a fashion that makes just the floor vent work

- - when you turn that drum gear, you'll hear that air rush thru in different ports

- - then you should be able to turn the drums gear to make the floor vent work and only the floor vent.

- Center it on the floor vent - for it may have some room of range for the drum to turn before it is only on the floor.

Why? Ford and some others like GM - "swish" the air between one port to another and back again to help stir the air and maintain some level of even-airflow in the cabin. I know the Focus does this - even on their manual system - to help keep the windows clear and you can keep warm on the colder days as it "oscillates" - you can even hear (and feel) the operation when at a standing stop at a light. You may also find the actuator seems to want to seek - this is that "swish" as it bumps the drum to make just the floor setting it's main setting and if left alone it may continue to seek.

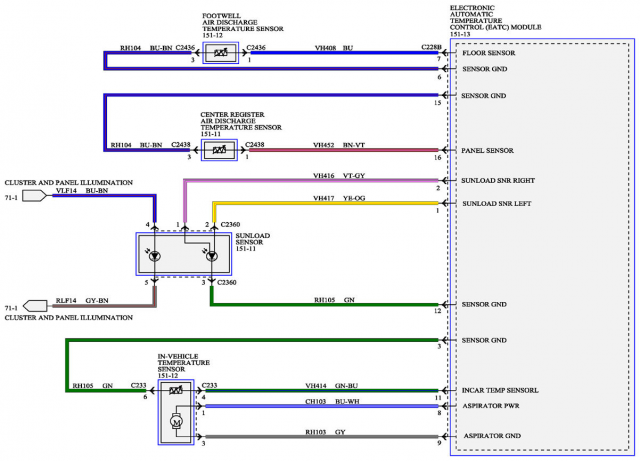

Now since I have only the Manual Climate - I do not see any mention, disclosure or any sort of extra "bottoming out" limit switches are used, just the positional sensors that are INTEGRATED into the Actuator - not the Drum itself. So the next step would be to find breaks in the wiring so an inspection is going to be done if the actuators pass the above test and only turn to a specific number of turns and sit there with minor corrections at any given moment in time.

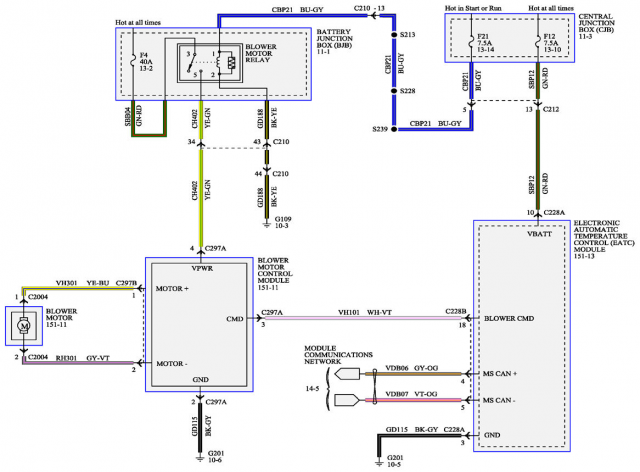

So if an actuator wiring harness is bad, you have to back-probe the wiring at the EATC end to see if voltage does arrive to the actuator and returns to the EATC

Continuing...

The best way to diagnose the condition is to make sure the drum can freely move to the various positions as the engine runs, the blower motor works and the temperature door actuator - is trying to close or open the door.

We Beat That Drum to Death...onto your original condition of Temperature...

Another thing to diagnose because it does happen; jamming the temperature door because something fell into the flap and now affecting the ability to open and close - did you recently have them change the Cabin Air filter?

In one instance - the service tech told of how the fuse to the heater blew, and so they simply replaced the fuse (Summer conditions) gave it back to the customer with the open invoice to make sure it works. It didn't (Close to winter) - so it was brought back and in this case the door was jammed by a screw that fell into the opening when they changed the cabin filter.

How that was discovered; - it was preventing the temperature door from fully swinging and would not blow the fuse, they replaced the actuator but it did not fix the problem until they look in past the filter and observed the door. The fuse blew to protect part of the climate system but took out the EATC unit controllers driver parts to it.

So it had no way to move that vane even though the hoses in the engine compartment were both hot from the fluid flowing thru it - the door / valve - stayed in that one position.

So the actuator was pulled and checked, seemed ok.

However, the EATC does not have a diagnostic for itself to say - "This is wrong" - they don't always have a code programmed in the DTC store to help figure this out - at least FORD didn't put any sort of programming in for it.

Many would have just replaced the EATC - only to be cautioned that the EATC will burn up again if the door is not checked for movement. It was in this test - did the service tech find the door / vane was binding and was able to use a magnetic fish tool to pull out the screw and restore operation. So one new actuator and one new EATC unit...

- What this means? The door got jammed, with an object - a screw - which can fall into the cavity where the Air Filter rests. If the screws were not all accounted for (I don't know) the screw or a screw, from the top of the console - can roll down into the vents and eventually work it's way down into places where it can bind or jam a moving part or hinge and prevent it from moving and can affect operation to a point that a catastrophic fault can occur.

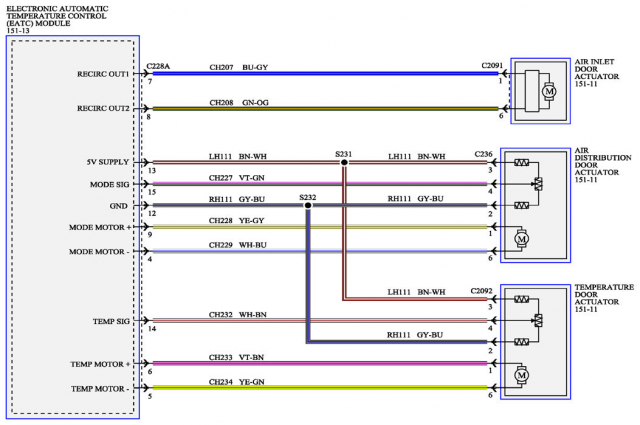

However - in all of this; look above in the schematics - the last one - shows the Motors - and remember that the power is DC - which means these motors will run in a given direction by the POLARITY of the power applied.

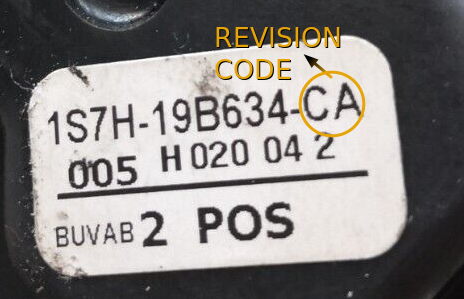

So two wires are power - but you don't or not easily find ground or power unless you measure it and can understand what the tools display is showing you - so look for MINUS symbols to understand the Door operations. The other three wires from these actuators send a trickle power - which when you look at the way the power flows thru the positional sensor - the cog it uses to follow the motor if the wiper arm is of a different composition reading (ohmic) it will affect the balance of the voltages read across these three wires to the EATC which then tells you you may need to either find a new actuator of the same revision code or replace the EATC and all the actuators - which gets cost prohibitive.

The problem then becomes the older units ohmic range is different than the newer ones which then means, the older EATC will need to be upgraded if you use new actuators because the older EATC unit can't figure out the position results when the arm moves due to the out of range readings the EATC can't process, so it can result in a burnt out EATC or snapped arms on the actuators - or both.

This is why the system power - the battery gets pulled so the EATC can see several things, including new readings that can help it zero the system and start anew. If the actuator is not of the same year or revision it may not be able to know "zero" or understand the current sense it receives (the level of voltage applied as current) so it can't understand where it needs to be so it will just spin in place until something breaks.

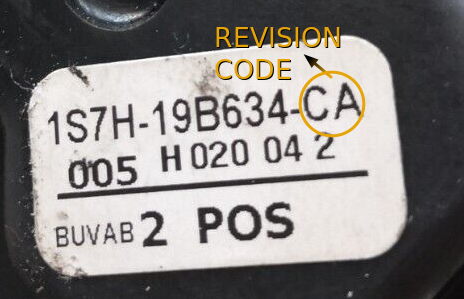

If you can - use a REVISION code

(last two characters of the FoMoCo String)

that is similar to what you have.

The closer it is,

the better your success rate will be

with and by the EATC recognizing it.

So, if you can't find any, or the one replacing it is a newer revision code than the OEM one broken in your hand - that may mean you will have to replace the EATC unit itself to use the newer actuators. OR cannibalize the actuator from the new and use old parts in it and keep the new arm - or somehow swap enough parts to make the actuator fit and run.