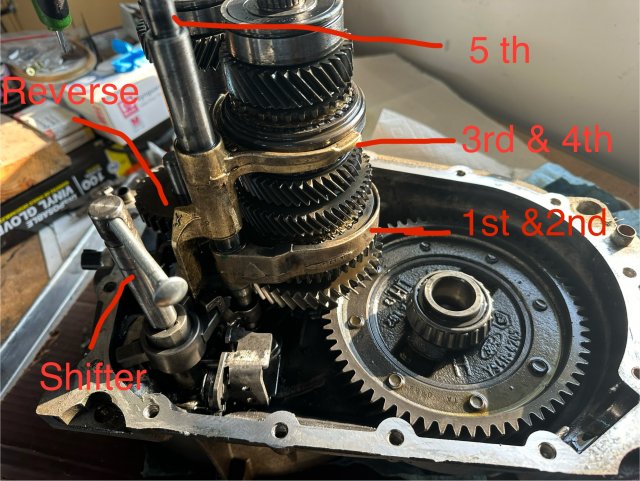

That little "L" shaped thing in your photos is part of how Reverse gets pushed onto and back out of being the counter-rotation gear set - the one odd gear, the one toothed in a way to only mesh with another gear uses that "L" as part of the 5th-and-reverse tine that pushes and pulls out the gear using that shaft the forks rest on and turn with.

If you (the others that will see this thread later) look carefully, that reverse gear is "medium sized" and only can mesh with only other similar-toothed gear on the shaft. There is no other gear set of the size - it's designed to allow one gear on the output shaft to mesh with that idler gear and only that gear

Part of any problem with manuals is the easy (or still) rotating set of gears when you have to hit the reverse and still make it mesh - the teeth are straight so it is a little funky to try and make it mesh - right off the bat, even when stationary.

So you have to gently release and spin the gears using the clutch to help the two gears mate up and work. There is no synchronizer on the reverse gear - when the gear set is aligned to sync with forward gears but not reverse. It's part of why the hypoid or slant gears are slanted in the direction of forward travel spin and synced to allow the gears a "window" to mesh the teeth onto the gear and accept torque as it spins up or down. That reverse gear needs to have a gentle nudge from the clutch and shaft spin to force the driven gear to move it's teeth so it can find enough room on the idler gear mesh to mate and mesh together

So to handle that stress of the reverse gear not quite meshing right - the gearbox distorts - that bar the idler gear is on, will twist and bend or move to try and fit onto the only gear it can - but it comes at a price. This can only happen so many times them the end cap - end-shaft bearings that make this float and roll - will wind up needing to be pressed out and a new set pressed in.

So the Reverse gear itself is not designed as the ways and means - but only a method in which to make the car change direction so it can be re-positioned to be driven in another.

It would explain the clank noise you heard and the difficulty in working the gearset afterwards - hopefully the rods that make up the shifter fork set and their forks are not bent to a point where they can't make the respective synchronizer mesh the gears together - if the shafts are fine, remember the pressed in end-cap bearing set has to take on that load - so it will have some noise and vibration from now on, it's usually not a big deal - but keep an eye on the seals for this vibration might mean there's more free-play pressing on the covers and seals.

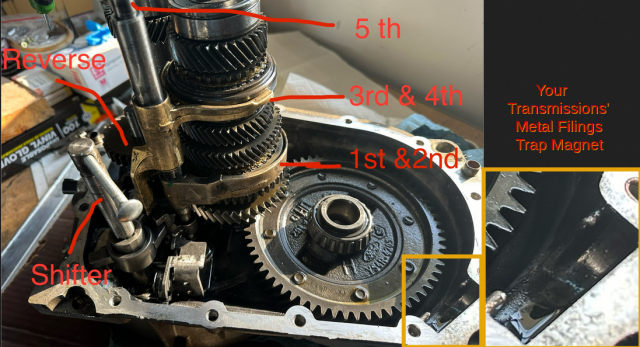

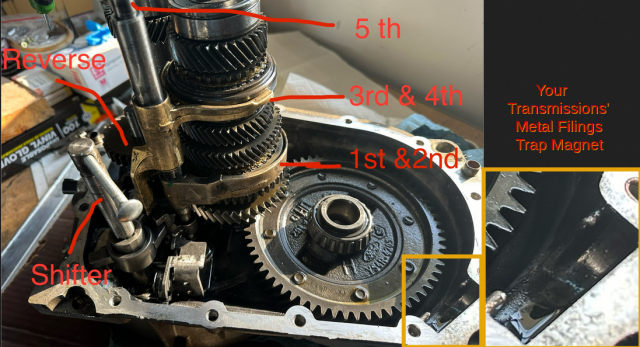

By what I see you didn't have a lot of shavings and you do have a magnet in there ...

So it seems to be in pretty good shape still!

So this means it may have a lot of miles left on it. Just don't try to roll the Odometer back unless the mesh can get burnished to make the reverse gear engagement easier.

To help with that type of diagnostics - during the install - it might need to just fit up the front wheels, work the transmission and use reverse gear to help clear out and burnish off any sort of burr of filings left in that assembly - grind them up to suspend them so they can make their way to the magnet on the back side of the housing (long end of the case behind the rear axle shafts) so they can be held fast there - that takes some driving in warm and hot weather to stir this up to make this magnet see it and hold it. The trans-axle gear has to fling this suspended stuff in the fluid towards it for it to even attract it.

So give it a drive - stop every now and then - stop somewhere, park, then back up and go about your business - like a shopping trip n' such - to ease your wifes' mind that she didn't destroy the transmission and the ease of your mind to let her know you forgive her and you become the superhero of fixing the car (again) so you two can enjoy a date...

Or, have to hire this guy to fix those lugnuts

and spend some time doing an overhaul.