Ok, this may require you to take apart the front steering wheel, that means removal of the Horn button and that contains the two bombs they call Air Bag (SRS Air Bang).

Why? Because the clockspring itself is not the issue, but the cover to house the switch both the Hi-LO-Beam and the Turn Signal and the other which houses the Wiper Front Rear - intermittent and WASH for both - will need to be inspected You can remove the upper and lower cover/shroud so you can see and check the connector. But the switch replacement - although simple, will require the battery to be disconnected so you don't have those airbang bombs going off while you're threading the switch into the housing/holster that you're pulling the old one out from.

- First Things First...

- Presuming you did check the hoses for blockage and cleaned the lines and nozzles.

- Fuses were good you were able to check the motor on a separate power supply and it works.

- The switch itself - uses DC but REVERSES the polarity to the motor to make it run opposite so the valve in it then forces fluid out a different port.

- So when this is checked - the leads of the tester can stay in place, but you have to verify the POLARITY of the meter does change from Positive to the Minus or Negative symbol - this would show the polarity of the wires are reversing - when you tell the system to wash the Front then you tell it to Wash the Rear - that is when the Polarity reverses..

Why does the Multitester show power to it, because of two things - one the corrosion around the MOTOR Spade (tang) Male/Female contacts that wiring is - may be - corroded. This makes a weak or resistive connection. Voltage may be able to be found there, but when you put in the motor - the power it needs might not be there due to that level of corrosion is enough resistance to prevent the motor from working.

The other may be due to the load the tester does not place on the connections. IF the measurement impedance of the tester (a rating) is HIGHER than the resistance the line has at the point you're checking - then the meter can show voltage - just not enough to let the motor pull the power it needs to make it work.

But, there is enough of a voltage to check but the leads being resistive due to the corrosion? Yes, it - might show a voltage but when you place more of a demand or LOAD on the line - can that power in voltage reading, stay up there to keep supplying that voltage?

How you do know?

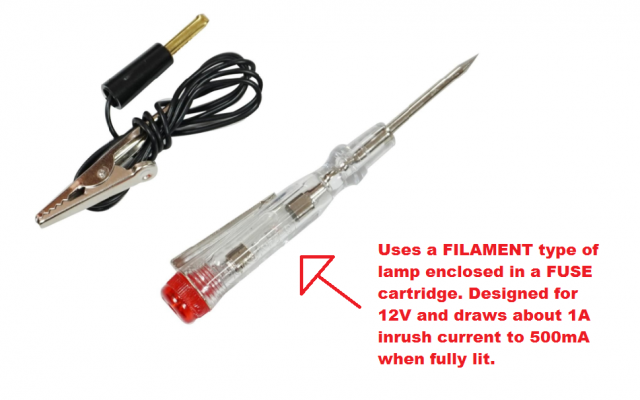

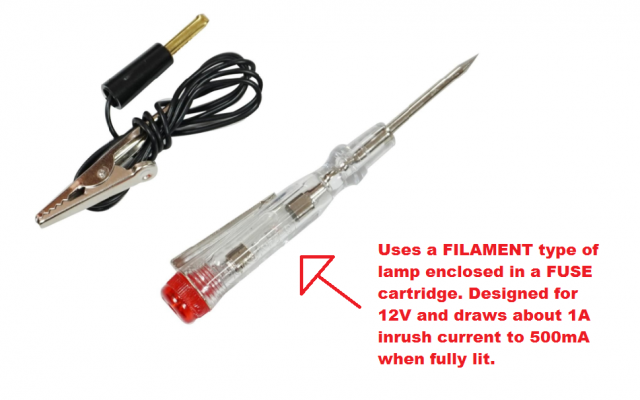

Use a simple circuit checker - the one that lights up when it sees power. You'll need to pull current too, so that motor if it doesn't work, you'll have to see if there is enough current to power it.

A multitester meter is a HIGH-impedance device - means that it is not supposed to load down the circuit it checks. It's designed to measure - not act as a load. So corroded wiring may show good and has power when checked using it, but you might want to check to see if it can pull the POWER needed to run the motor - that requires Current - not just the voltage. but due to the RESISTANCE in the connection at those contacts - the wiring is not able to support the current draw needed by that motor to run (about 2 to 4 Amps) that the switch on the steering column has to support.

Then if the lamp lights, the connector(s) need to be worked up or tweaked to make contact similar to what the OEM original one had used and oriented as, for the original life time it was in that position. So you may need to clean it out. Some people due to the age of the connector - simply buy a pigtail and wire it in to replace the old connector with a new one.

- It is not uncommon to have the connector and the pigtail - even though they have the same pinout, same connection figure, and even the proper tabs - and tangs male and female - they should fit right?

- You will need to verify the tabs on the body of the part, will match and fit with the connectors own.

- This has been a issue with aftermarket and ordering parts for older vehicles that are no longer in production or supported by their automaker.

- The connection on the replacement part, has a different size tab so the electrical connector may seat, but the tabs never make connection because the tab to socket are the wrong size and or cannot reach their mate in the body of the connector.

IF that doesn't you'll need to backtrack, backprobe the wiring harness to find the break or poor connection so you can splice or replace that part of the harness. This also includes all the way back at the dash console and steering column.

I will caution you, the harness - being where it is, can set off the SRS light because of the amount of work that has to be done in there, so the tilt and telescopic steering wheel it is, can wreak havoc with the harness - even thought it is designed to fit and work within the reach - we cannot be held responsible if the SRS system ignites while you work on the dashboard.