Then the creak is from strut mount in its bearing cup. That area - but to be specific is a little tougher than a simple "ok, then do this..." approach.

IN the process of elimination - I'm trying to help you narrow down to an area - so the top nut although not difficult to tighten or loosen - does have a keyway - so as you tighten the nut, if it's not in the keyway, the nut and shaft will turn - and generate a creak, squeal or a rattle on bumps and takeoffs that can make it seem like the wheels ready to come off. It's simply from the torque the strut bears during acceleration while it attempts to drag the rest of the car it's attached to, down the road with it.

The Strut Top nut also has a mating hex keyway on the top so you can use a spline Go-Thru tool to obtain grip on the Top Nut and then, thru it, to hold the hex wrench on the shaft of the strut - to hold it - the shaft - from rotation while you tighten down the top nut to specs.

OR once the struts removed - you can simply use a 6mm Hex wrench and an 18mm Deep Set Wrench

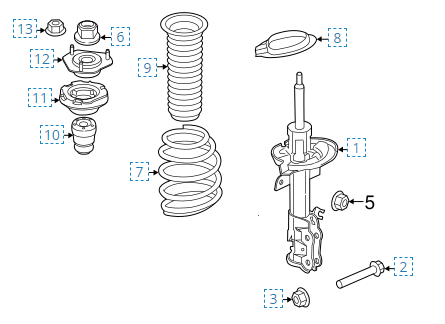

The Bearing cup, on the other hand, fits between the struts shaft sleeve (that bellows cover to protect the piston) and the bottom of the strut top mount - the two get (set or sit) together and the strut shaft goes thru both - into that top strut mount.

The Bearing cup rests above and into the spring - below the strut mount but uses the Strut Shock shaft rod, thru it onto the Strut top mount - so the spring compresses into the bellows and bearing cup and that assembly rests in the form of the struts mount - with the strut inner shock bearing (or hockey puck) takes on the Top Nut and that shaft - bolts and hods both together as one unit.

The Cup uses roller bearing and race setup to roll and bear weight of the strut into the top strut mount - if that is not completely flat- a creak or settling can occur and the bearings inside will tend to creep out and find their own balance in the rest of the cup race - generating a flat-spot that the roller bearings stay out of and once installed the bearings don't return to it because the limited steering (axis) rotation of the tires are not 360 nor even 180 more like 95 to maybe 110 degrees rotation, the bearings themselves vacate and find their own resting spot away from the main bearing weight point - like it got squeezed out. Again, another type of groan or creak you'll hear...