Sounds like you've got this, but to offer some more help...

The Actuators consume a lot of power at a given moments notice - so the Alternator might need to be serviced or at least check that serpentine belt - if it's loose or worn it can cause a dropout where the regulator can't quite give the actuators the power they need to shift the forks. They spin but won't engage and cause that rattle and slip - even a grind or two from the lack of ability to push then into gear because the alternators' not there to help give it that push.

Had that happen on other Ford's in the fleet - Focus' are prone to this due to their exposed battery cable issues.

Check the Alternator output post and even those wires on that regulation connector and make sure that copper bolt is clean - there is supposed to be a rubber threaded cap that goes onto that post. If it's not fastened or has a weak grip / seal to the post, the corrosion in the section can cause those high-current demands not to get met and if it gets wet will cause a belt to fail - even catastrophic one - taking out the alternator itself.

Here's a quick test to help you in finding proof of the battery or wiring cables are causing this issue.

Find a use a DVM that is RATED and fused for this...

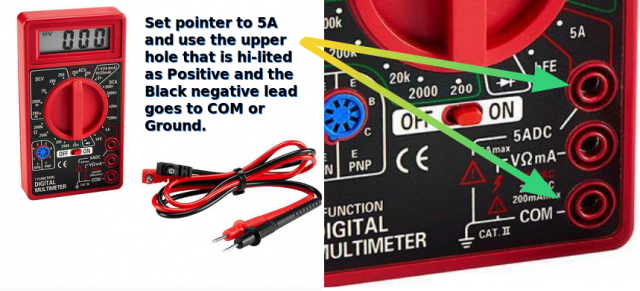

Take your DVM - set it for 5A DC setting (

First; Test using a Higher Amperage setting - the meter is wired in a way to let it use a SHUNT in the meter as a measured level of resistance across the connection. The meter will simply sample it.) - connect the test leads for Current (A or I post hole) and of course - Ground (Negative - )

Start your car - let it warm up and idle for a few minutes to let the battery and charging system stabilize...

Positive Red test lead to that Alternator output post.

Negative lead to the Positive Post on the battery - not the starter alternator connector - the real positive post on the battery itself use a clamp if needed to help.

Turn on your headlights. Watch meter.

IF the reading goes up but stays below 100mA the Test passes. The system might need work if it's gone up past 200mA though - it means corrosion or needs help in getting power to the battery and the rest of the system.

IF the fuse blows in the meter - stop - the test failed and you've got issues with the cables to the charging post on the battery - the simple effort of the system pulling of current - if the cables were good - would have been less than that DVM's fused side. Since the fuse blew - shows the cables are corroded or have a high resistive connection that needs to be fixed - the DVM was connected directly ACROSS that bad connection - so the alternator pushed the power past that resistive connection using your DVM to do it. It found a easier path to push current to the demand - blowing the fuse inside the meter - you're meter is ok, just needs a new fuse.

- IF your DVM has a 10A setting - do this test using that post FIRST to help reduce the fuse blowing - it will not be as accurate but the initial test shows that the draw - if it's below 200mA then you can use the reduced setting which makes the DVM more sensitive to changes in current as loads are put on and turned off on the system.

IF the DVM Reading goes up past 100mA - the Cables and connections to the battery need help so you're going to have to clean up the connections and repeat this test until that mA reading is even below 100mA - which is possible on a new OEM system with clean connections and fresh set of cables to do this.