No, not a true "Limp Mode" like engine, but a weaker state of operation. It can't "boost" the power it would otherwise have available because the Alternator and the PCM aren't able to talk (this is like a symptom of "I can't hear you due to all that noise") - which may indicate another more subtle but far more serious and devastating condition of producing AC power mixing in with the DC level which can be very dangerous.

You mention you're an older car guy, yeah, that's me too - from the older days of rebuilding several Delco-Remy Alternators so I can keep my old 76' Pacer (amongst other rust buckets from friends and family) on the road - those days are gone.

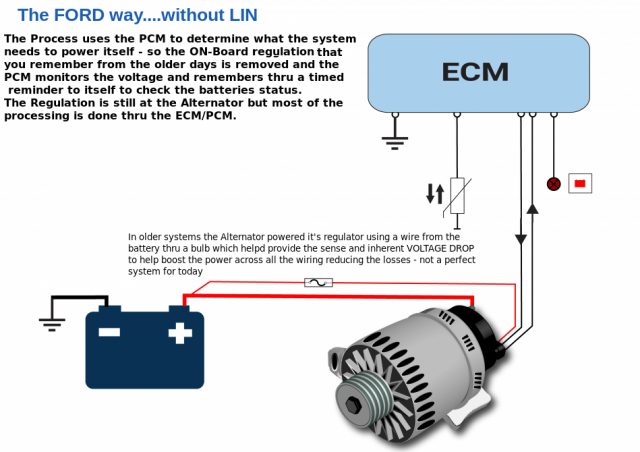

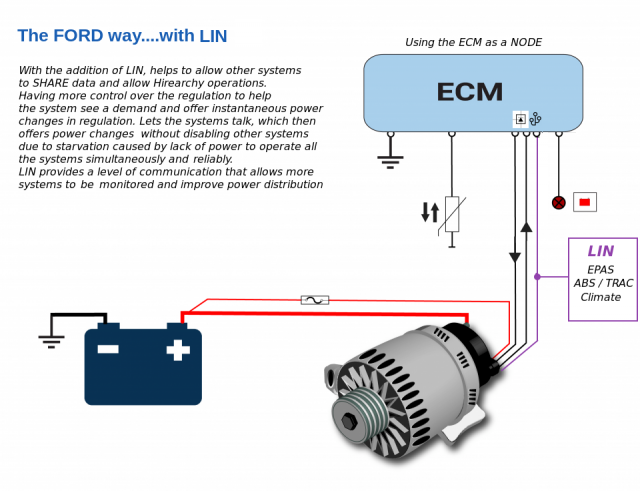

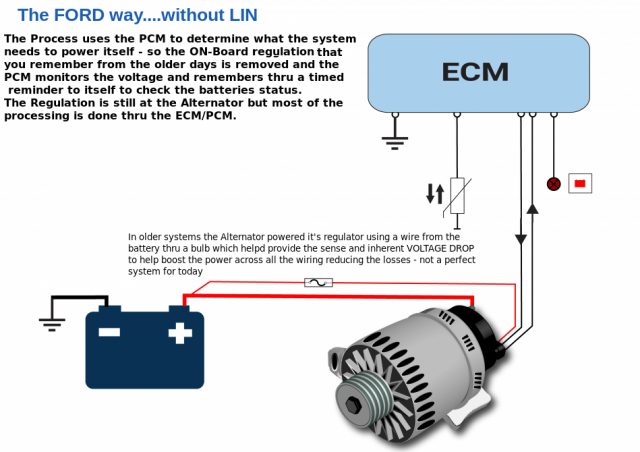

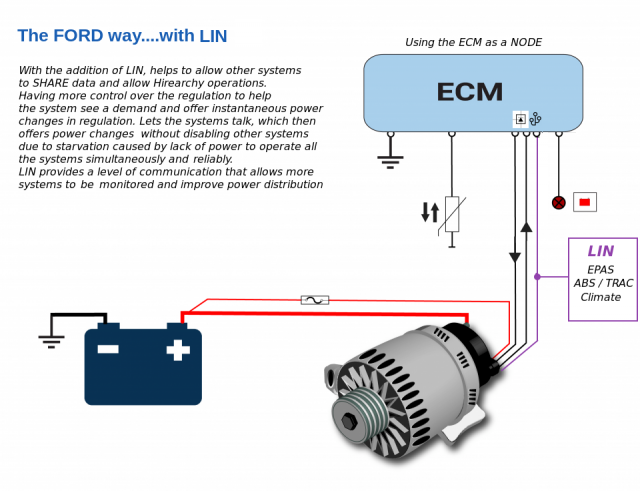

Today's cars - the Alternator is no longer a "self-sufficient" charging system. It now uses the PCM to help develop an energy budget, so it uses a means to talk to the Alternator so it can produce the power at moments of need at greater rates than would be safe for the battery and or the system itself - for the surge could damage the parts connected within. That's why I mentioned the LIN system, it's like the older telephone systems - they supply DC power to the phone but can also send voice and data - we eventually worked it into making PC's talk to each other like modems did back in the 90's. The LIN system uses the DC power and Telecommunication transfer technology to listen for commands and even send data back onto the line for the PCM to interpret a condition and if properly programmed - make up a budget to handle the demands - Like EPAS and ABS / TRAC-control systems along with lighting and regulation of power to keep the system working and charging.

So when you say the car dies when it's at idle - seems more like a "Stall-condition" which may mean something else is causing this, it may not be from a poor charging system condition.

You may need to verify that the alternator is not causing this - which means several checks - some simpler ones are like listening to your AM radio in the vehicle and listen to the stations you can get - listen for the background noises as spark plugs make a popping noise and static from your fuel pump may be heard as short bursts - all while you rev the motor up and down. It should be pretty quiet even in-between stations and while listening to weaker ones - if you hear a high-pitched whine, that varies in pitch as you rev that motor, it my mean your alternator is weak - it may mean you'll have to replace it soon - as in it can also indicate a bearing in the Rotor shaft is getting ready to seize on the belt - leaving you stranded.

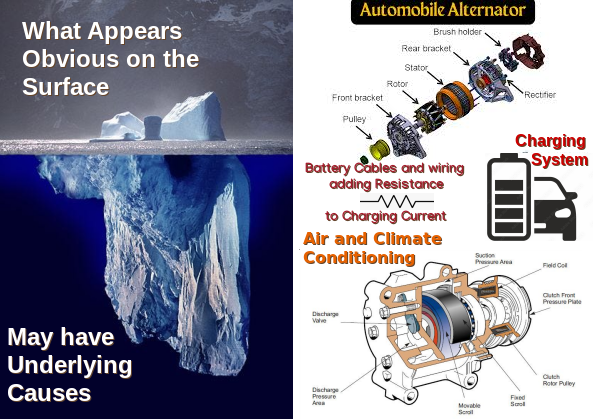

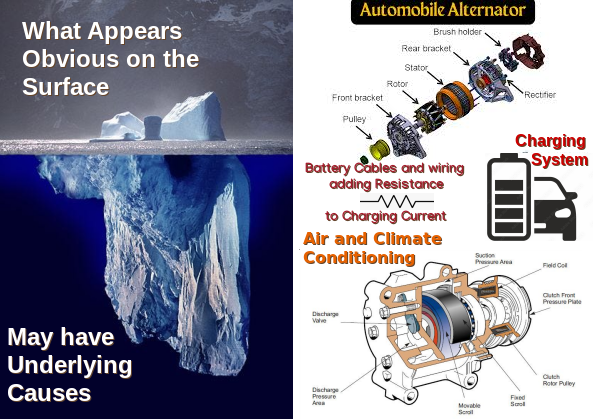

This is just the tip of a big Iceberg...

For you may have to check the output of the Alternator is it producing DC or maknig a lot of AC?

Regarding - knowing it has bearings, they can drag and pull power away from an idling engine - that will stall caused by the system can't make the rev-up to help the car move.

Also - make sure the AC compressor is not causing this condition if you have the Climate Control working Defrost or using any setting that has the Windshield symbol.

The Drag is what I'm talknig about - the physical loading down of the motor - can cause it to stall.

For engine loading can cause this same condition - so check your systems. It's also possible that the compressor in the AC system is dragging on the Serpentine belt and pulls down the idle to a point of stalling the engine - this can also be from the Alternators own pulley and bearings seizing - doing the same thing, trying to pull the idle down to stall the motor and you're trying to restart the motor. This may be a thermal condition of the bearing overheating when the engines warmed up - the starter has to fight this drag to even turn the motor over - that can kill the battery too.

If you remember previously in this post - the issue of rebuilding older Delco alternators - mostly due to the Diode Trio failed, the diodes are supposed to Rectify current produced as AC in the coils, to DC with a lot of pulses - like 3-phase AC converts to DC - you get a lot of sine waves converted to humps, only now on one side of the voltage rail - being now it has a DC pulse component and no longer AC.

- Many of those electrical problems were caused by the diodes module failing - either by a shorted diode or a blown diode.

- When the system could not charge the battery very well, you could hear the whine if the speakers at any given volume level - for the alternator was producing a ripple current mixing in as AC instead of a pulsed DC.

- So what to do?

- Use a DVM - a means to check for AC ripple is to use the AC side and see if a ripple voltage forms on the DC line at the post of the battery - and test at the Alternators' output post.

- Since Alternators output are pulsed DC, it's smoothed by the Battery's own ability to act like a giant capacitor taking up and pushing out charge - so it can filter this ripple into a very low-level of noise.

- However, - a resistive element can develop along the line - this is why I mention impedance - because of the AC component formed - affects how filtering and power losses occur as a voltage drop from the filtering needed - also affects the charging current present to even move power across that bad resistive junction or wire.

- The Better the connections (Read lower resistance at high-current flow rates) the lower the ripple and noise factors due to it.

- For you don't wind up starving the system as a result of a voltage drop occuring when high-current levels are demanded.

- Ripples can be detected using AC or you can also find the culprit by measuring from one point of known good connection - to another connection point like the positive battery posts in DC - and you can see a voltage drop in DC due to the power the alternator is able to supply is not getting thru the tested junctions, but using the ohmmeter to send that power to the battery - because the meter bypasses those bad connections and flows into the battery which is at a lower potential - it needs charging. The LIN system tries to boost that power - but if it's too high - the PCM can set a code casued by the LIN system telling the other systems it's already at a higher level than it's designed for.

- So you can find ripple in one place but due to the batteries own influence on this can fitler out much of the ripple as it shows up as a votlage drop from it. Resulting - as a reduced abiltiy to be shown as "I need some charging!" condition

- Blown diodes cause poor charging and fading of the lights brightness amongst the lowered or less ability for the heater system to blow air - until you revved up the motor and you'd hear it return to set speed or see the headlights and dash brighten back to original settings - along with that Radio whine.

- Shorted Diodes cause battery drain along with similar symptoms as told above, so the battery to "die" can mean several events up to and including the charging output post on the alternator is pulling current when the engine is off, so since it's connected to the battery all the time, the battery discharges into it - aside from the Age of the Battery being that the plates sulfated or the cells within it are causing shorts (reduced lead decreasing the resistance or the lowering an impedance appearance of a fully charged battery) forcing the alternator to push more power into the electrical - forcing itself into a potential shortened Mean Time Between Failures - and fail catastrophically.

- In a fresh or fully connected system that has good connections - ripple doesn't appear as a factor of performance - It's when the wires corrode at the terminals or the places that are fed by it can't pull power due to the corrosion or resistive- impedance losses - effect - the ripple starts to become more prevalent and can become dangerous to the low-power systems. Those systems, even though they although are filtered and regulated - can still get knocked out by the spikes formed from charging loads, and their variances being unable to be accommodated for affecting the ability of the wires to even supply current from the alternator that. in itself - can't see those effects because it only knows or sees, a given resistance to the current it tries to push into the system to keep it charged as to a level it thinks it should be. E.G. - Alternator output at the output terminal may be 14.4V, but the Battery only sees 12.6V from it.

- That the reason for the LIN - a type of monitoring the PCM can call out to. It's used to verify the integrity of the system - it's not foolproof. In using it in a simpler system like the Fiesta - in it's simpler form - can only help in those pinches as needed to operate heavy current demands. But, in other systems from FORD they programmed it to become a reminder so the Battery itself can be checked and "tested" by the system and notify you to check it. Some Titanium and Platinum models (upper trim lines) have this LIN as a Battery Minder System (or similar wording)

That's why I mentioned the rebuild, for your battery seems to hold a charge, but if parked - will drain. So if the battery is physically failing - that's one thing, but if the ELECTRICAL side of this is failing too, them both (Alternator and Battery) are at risk and can take out your cars more important modules.

So you may need to not only replace the Battery, but repair it's connection points to the main Battery Junction Block - that big RED capped set of terminals on the Positive battery post. And then verify the Alternator is working and is communicating. The Fiesta uses a LIN system, but it's functionality varies in the trim lines it's used in. So to replace the Alternator - it will require an exact re-fitment of the OEM part for the LIN to continue working.